The case study below demonstrates how PicoScope fits within the diagnostic jigsaw when resolving seemingly complex issues.

The analogy of a jigsaw fits well if we look at the essential pieces required for a successful diagnosis.

- The relevant Scan Tool

- Accurate technical information

- Experience gained as a direct result of training

- PicoScope

The vehicle in question is a 2001 Toyota Celica 1.8 190 PS utilising variable valve timing and lift.

The complaint from the customer was poor idling, heavy fuel consumption, lack of power, periodic cutting out on over run and the all-important engine warning light was illuminated.

As always the customer interview is vital, and in this case revealed that extensive engine work had been carried out including a cylinder head replacement due to severe overheating.

At this point it is very easy to jump to conclusions and assume "doom and gloom" when a customer arrives having experienced numerous attempted repairs after a major engine overhaul, however, by maintaining a methodical approach throughout the diagnostic procedure we can present our customer with not just a bill, but a working vehicle and the evidence and data trail that supports the necessary rectification.

A basic inspection revealed the tell-tale signs of intrusion about the engine to include, a new cylinder head, VVT oil control valve, coolant temperature sensor, catalyst, pre-catalyst O2 sensor accompanied with a punctured and misrouted wiring harness that resembled a pin cushion! A brief road test confirmed the customer's complaint but also revealed the engine to sound fine with no knocks or rattles, or smoke from the exhaust and both coolant temperature and pressure to be correct.

Note: The exhaust fumes did emit the sulphur odour associated with over fuelling or a catalyst working overtime! (it is essential to establish the engine condition before spending the customer's money).

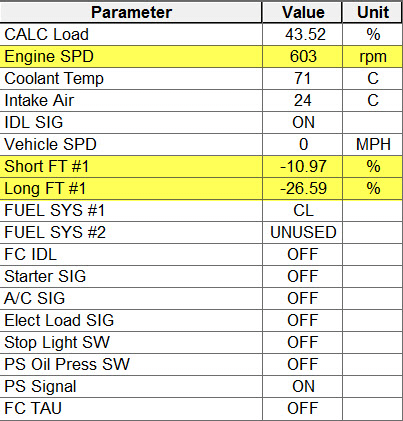

To begin, the scan tool (our first piece of the diagnostic jigsaw) was connected and fault code P0172 recovered with the relevant freeze frame data.

P0172 refers to "System too Rich" whilst the freeze frame data confirmed fuel trim figures attempting to compensate for the "Rich" fuel condition at idle (Long FT -26.59% Short FT -10.97%)

The negative fuel trim value indicates the PCM has been progressively reducing the amount of fuel injected as a result of information returned from the O2 sensor (O2 sensors report a rich condition, the PCM reduces injector duration until the O2 sensor reports a lean condition).

This form of closed loop fuelling will continue for as long as the total of the long and short fuel trim values remain within -25%.

In the case below our total Fuel trim values -26.59% -10.97% = -37.56% and so P0172 is stored and indicted to the driver via the MIL.

Code P0172 freeze frame data indicates error occurred at idle speed:

|

Here is where the scan tools come into their own as both the fault code and freeze frame data provide the all-important reasons why the MIL is illuminated and a historical snapshot of events that were present when the PCM recorded the fault code P0172.

So where do we start with an engine running too rich?

The description of rich here would be insufficient air or excessive fuel and so keeping it as non-intrusive as possible, the intake, exhaust system, evaporative loss and engine breather valve were inspected for leakage and restrictions that could influence fuelling or breathing, all were OK.

A gas analyser check confirmed Hydrocarbons to be high on arrival at 305 PPM, falling to 17 PPM at 2500 rpm and initially remaining low on return to idle, but increasing during the unstable idling condition.

Here we know that idle fuelling is incorrect (producing 305 PPM HC) and fast idle fuelling (off load) to be correct as the catalyst is performing as intended.

O2 sensor signal and fuel delivery pressure at idle were both next for scrutiny as either have the potential to influence fuelling to produce a rich condition.

Fuel pressure was fine at 46 PSI, however the O2 sensor signal was stuck rich at idle speed but switching correctly above 2000 rpm.

Let's evaluate what we know and form the all-important action plan:

- Code P0172 has been confirmed via gas analyser and O2 sensor signal remains high at idle.

- O2 sensor switches correctly at fast idle confirming the O2 sensor to be functioning.

- No leaks or restrictions within the intake or the exhaust.

- Fuel tank and engine breather systems to be functioning correctly.

- Vehicle fuels correctly at fast idle (off load) and fuel pressures are correct throughout.

- The engine is efficient with no mechanical issues.

- No misfires are evident.

- Vehicle lacks power from rest but performs OK when cruising.

Here is where the second and third pieces of diagnostic jigsaw join to form our action plan. Technical information and Experience gained as a direct result of training allow us to evaluate all that we know.

The engine is rich at idle but flat and lacking in power when accelerating (remember, "System to rich" equals lack of air or too much fuel).

A decision has to be made here of which system to pursue and the major deciding factor is ease of access accompanied with the time involved to evaluate.

Based on all the above and experience gained, the air intake metering has to be the obvious choice of where to deploy the final piece of the diagnostic jigsaw... PicoScope.

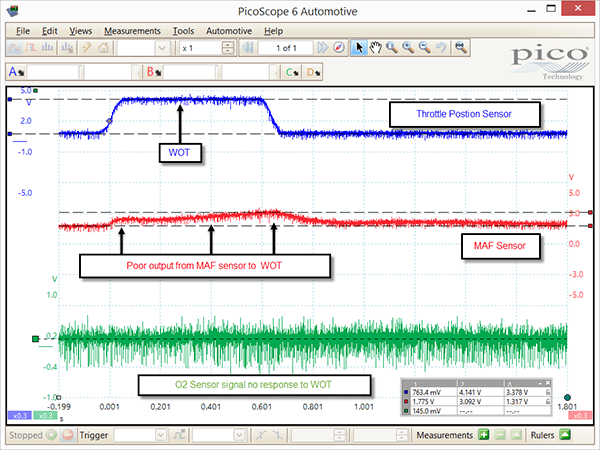

Looking at the intake tract the scope was connected to assess the relationship between the throttle position, MAF meter response and output and O2 sensor signal.

|

At last a breakthrough, the Hot Wire MAF meter response and output was nothing short of dismal given the difference between idle speed MAF voltage and Wide Open Throttle MAF voltage was 1.31 V! This sits well with the symptom of poor performance from rest and could not be the result of a mechanical condition as the engine could achieve high RPM on road-test (just delayed). However, how does this fault within the MAF sensor generate a code of P0172 (system to rich) when we clearly have a system too lean under acceleration? Generally speaking a MAF meter with this style engine will range from 1.2 V at idle to approximately 4 V at WOT (see below new MAF installed)..

|

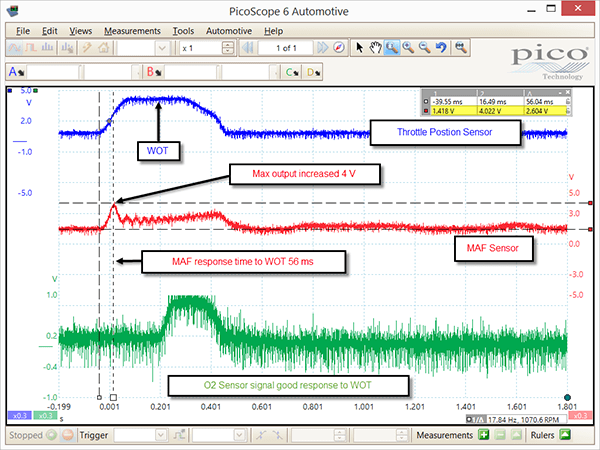

Here we can clearly see an excellent response time of 56 ms for the MAF meter to WOT accompanied with an initial maximum output of 4 V. The O2 sensor now responds to the change in fuelling as enrichment takes place during WOT unlike the original capture.

A point to note here when installing a new MAF meter to replace a faulty unit:

The engine management fuelling will have adapted to the feedback and response time of the original MAF meter and so PCM fuelling adaptions will need to be reset or, the vehicle driven over a specified period of time to allow for the PCM to adapt progressively. I have seen MAF meters installed momentarily during substitute diagnosis only to find no improvement because the PCM has not been allowed or forced to adapt. The faulty MAF meter is then reinstalled and the incorrect diagnosis continues (Technical information and experience as a result of training come into play here)!

To recap, the new MAF meter has resolved all the symptoms mentioned and a re-check of the scan tool data list confirmed the fuel trims to be levelling out and O2 sensor to now be switching at idle (previously stuck rich). These results indicate the MAF to be faulty 3 fold, over-reading at idle, under reading during acceleration and poor response to WOT.

It was the over-reading at idle that got me thinking as I had not seen this fault before with a MAF meter, only under reading and poor response (often generating P0171 "system too lean").

Closer inspection of the faulty MAF meter waveform revealed an idle speed voltage of 1.775 V where the replacement MAF sensor was 1.418 V (faulty MAF meter reading 20% higher for the same engine speed).

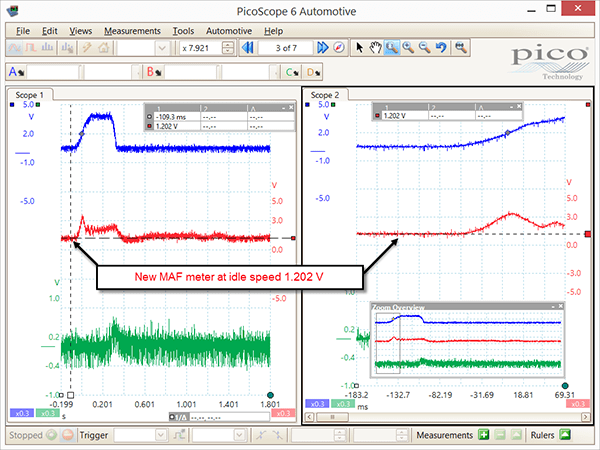

As a result of this revelation, further acquisitions of the new MAF meter were taken and the average idle speed values recorded during repeated 'idle -WOT - idle tests'. These were found to be even lower at 1.202 V, meaning our faulty MAF meter was actually reading 32 % higher at the same given idle speed!

|

Additional Hotwire MAF meter information

By design, any contamination of the exposed sensing element will alter the operation characteristics (cooling) of the hotwire assembly. Therefore measuring the MAF sensor signal wire with the ignition on and engine off will provide an indication of contamination level where high contamination level will result in a high output voltage. Refer to the relevant technical information for key on, engine off values.

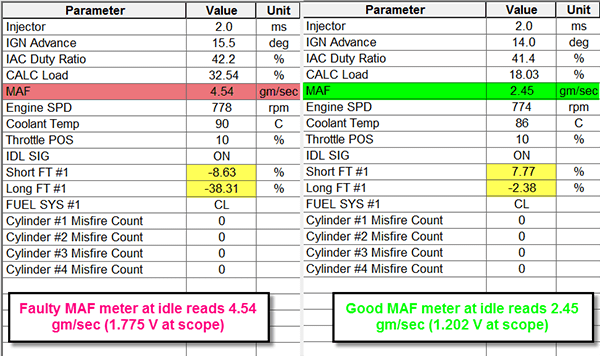

This is where we return to the scan tool and the live data captures taken before and after replacement of the MAF meter to confirm the findings of the scope. Remember an increase in airflow results in an increase in the output voltage of the MAF sensor:

|

The scan tool live data capture has the faulty MAF meter reading 33% higher than the replacement but keep in mind:

- We are looking at a snapshot in time and this figure is constantly changing.

- The update speed of the scan tool has to be taken into consideration.

- What we are looking at is the PCM interpretation of the MAF based on a number of engine operating parameters.

Our PicoScope is purely looking at the real-time output voltage without any manipulation. When all is said and done, both tools are reporting the same condition, the over voltage output from the MAF meter (at idle) is responsible for the incorrect over fuelling condition at idle speed.

Calculating theoretical MAF values

As a basic indication of airflow, using the formula below we can estimate MAF for any normally aspirated engine speed (assuming a WOT):

(RPM X ENG CAPACITY in LITRES) / (60 X 2 INTAKE STROKES PER REVOLUTION)

E.g. our normally aspirated 1.8 litre, 4 cylinder, 4 stroke engine running at 3000 rpm would consume:

3000 RPM / 60 = 50 Rev per second (Hz)

For each engine revolution of our 4 cylinder engine we have 2 x intake strokes

Therefore 50 rev per second / 2 = 25 intake strokes per second

25 X 1.8 litre = 45 litres per second

Note: Air mass is approximately 1 gram per litre at sea level (pressure and temperature dependent).

Therefore 45 litres per second is approximately 45 grams per second (45 gm/sec).

Technical information allows formulas as those above to be implemented during diagnosis to evaluate test results, presenting a real advantage to those who invest in the jigsaw.

We can use the formula above to create a Maths Channel that can be applied to the crankshaft signal of any normally aspirated 4 stroke engine in order to display the theoretical MAF value during our WOT test (remember if we know the engine speed, number of cylinders and the engine capacity we can calculate airflow).

Now we can cross reference this value against the scan tool data list to confirm the integrity of the MAF meter and ultimately the ability of the engine to breathe. Do not be too alarmed if the maths channel value does not match the scan tool MAF value under WOT at a given engine speed as we are calculating the theoretical value only. However, the scan tool data list should display a value marginally close to the theoretical value and not excessively over or under this value.

So how do create a maths channel?

Below we describe how to create two maths channels, one to calculate RPM and the other to calculate MAF. Only the MAF formula is relevant for this case study but including the RPM formula for this vehicle enables the technician to see both RPM and MAF (Maths Channels are applied after capture when reviewing the waveform).

Calculating RPM

The Celica Crankshaft pick up ring has 36 teeth with 2 missing as a TDC reference. Whilst in reality we have 34 teeth, we must include the missing teeth in our formula for accurate RPM results.

To explain further how the maths channel can display RPM we need to look at the theory below:

- Frequency is measured in Hz (Cycles per second)

- We are looking at the frequency of the engine speed signal in Hz's but require RPM

- RPM = Frequency (Hz) X 60

PicoScope measures the frequency of 36 teeth of the crankshaft sensor pick up (1 crankshaft revolution) and multiplies this value by 60 (seconds) to obtain RPM :

36 Teeth of our crankshaft pick up are equal to = Hz x 60

The maths channel formula for RPM is written as follows: 60/36*freq(A)

With your captured waveform on screen select Tools>Maths Channels and then Create. Click on Advanced and type "60/36x" in the formula box, then click on the freq button. When "freq( )" appears in the formula box, put your cursor in-between the two brackets "( )" and type "A", the whole formula should look like 60/36*freq(A).

Click Next, choose any colour you prefer for your RPM maths channel, in the Units section type "Engine Speed" in the Long name box and "RPM" in the Short name box. In the Range select box it is best to set a manual override for the actual range you require (in the example below I have selected 0 RPM to 7500 RPM) and finally click Finish. Click the box next to your created maths channel to enable it and click OK. A new (maths) channel will appear and will plot the RPM of the channel you have requested.

Calculating MAF

The maths channel formula for MAF is written as follows:

60/36*freq(A)/60/2*1.8

PicoScope calculates the RPM (as above) but now incorporates the additional formula to account for 2 intake strokes and a 1.8 litre engine

Once again select Tools>Maths Channels and then Create. Click on Advanced and type the exact formula as above for RPM 60/36*freq(A)Â but now add /60/2*1.8.

The whole formula looks like 60/36*freq(A)/60/2*1.8

Click Next, choose any colour you prefer for your MAF maths channel, in the units section type "Airflow" in the Long name box and "gm/sec" in the Short name box. In the Range select box it is best to set a manual override for the actual range you require (in the example below I have selected 0 to 130 gm/sec) and finally click Finish. . Click the box next to your created maths channel to enable it and click OK. A new (maths) channel will appear and will plot the MAF of the channel you have requested.

Below we have the waveforms from our donor Celica looking at Crankshaft signal, Throttle Position, and good MAF. We now also have 2 maths channels indicating a Max 7003 RPM and a Max 106.2 gm/sec MAF. The peak values of the maths channels reveal the measured values of interest. The regular downward spikes are characteristic of the missing teeth from the crankshaft sensor pick up ring.

|

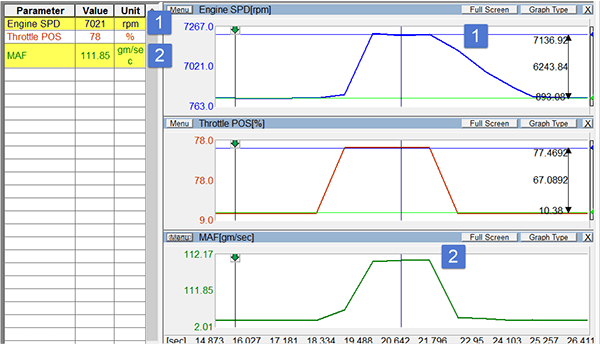

Below we have the serial data from our scan tool displaying Engine SPD, Throttle Position and MAF as a line graph. Note the refresh rate (update speed) is poor with only 3 parameters selected. Comparing the serial data results to the scope we have a Max engine speed of 7021 RPM with a Max MAF of 111.85 gm/sec.

|

So here we conclude the case study and I hope highlight the relationship between PicoScope and Scan tool.

- The Scan tool revealed the code, freeze frame and live data.

- Technical information provided vehicle specific values, locations, diagrams and procedures.

- Experience/Training enabled the technician to develop a logical process with relevant system knowledge to form an action plan.

- PicoScope revealed the faulty component outside the detection condition of both the PCM and Scan tool (in real time) presenting accurate and conclusive proof of component failure .

When looking how the customers issue was resolved, the pattern is a repetitive one where numerous parts are installed after multiple garage visits yet the solution came from an individual who has invested in the applicable Scan tool, Technical information, Training (gaining experience/knowledge) and applied the essential part of the diagnostic jigsaw...PicoScope.