|

|

||||

| Log In | ||||

|

| ||||

| ||||

| ||||

| ||||

| ||||

| ||||

This 2009 (MK3) Renault Clio 1.5 dCi engine had a complaint just after starting where a strange noise occurred for a few seconds followed by the MIL illuminating and the engine entering recovery mode. A quick scan revealed the following stored codes:

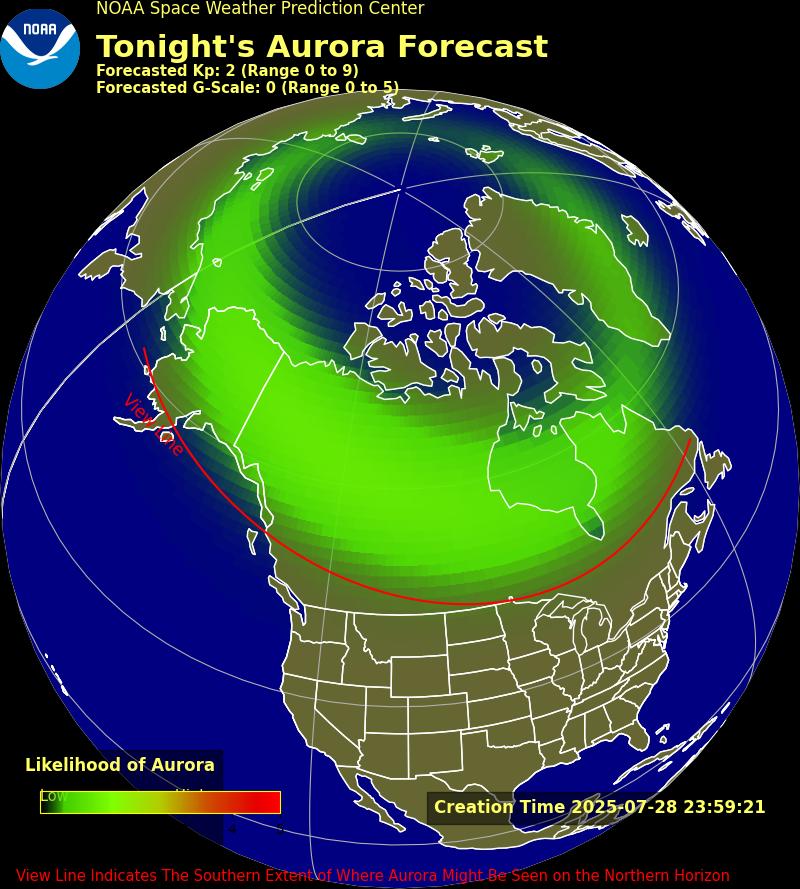

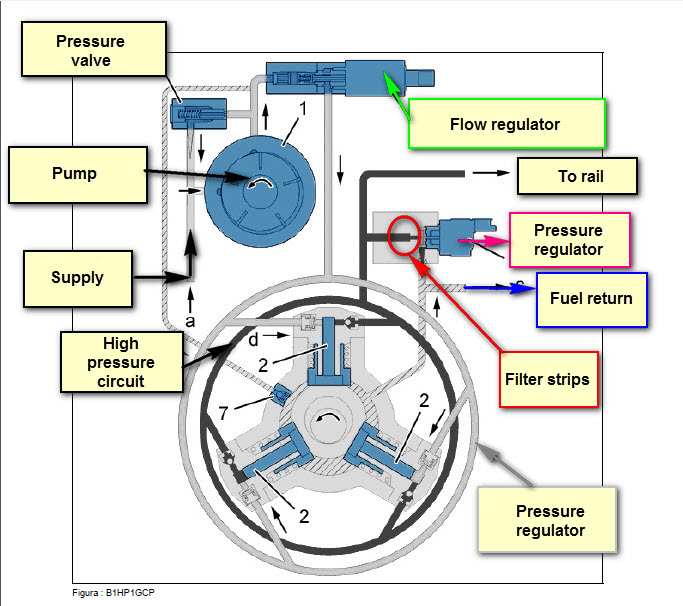

This engine uses a Siemens SID 305 control unit with a flow regulator to fuel pump inlet, and a pressure regulator at the pump outlet. If the inlet receives no signal from the control unit no fuel enters the pump, resulting in no pressure in the fuel rail. When the outlet receives no signal from the control unit, its internal spring regulates the pressure in the rail at just 50 bar.  With regard to the problem of too high pressure we have to verify which component creates the problem. I decided to measure the flow regulator voltage (CHA) and current (CHC), the voltage signal of the pressure regulator (CHB) and the sensor signal for rail pressure (CHD).

The two solenoid valves are controlled in PWM, so with two Math Channels we obtain the percentage value:

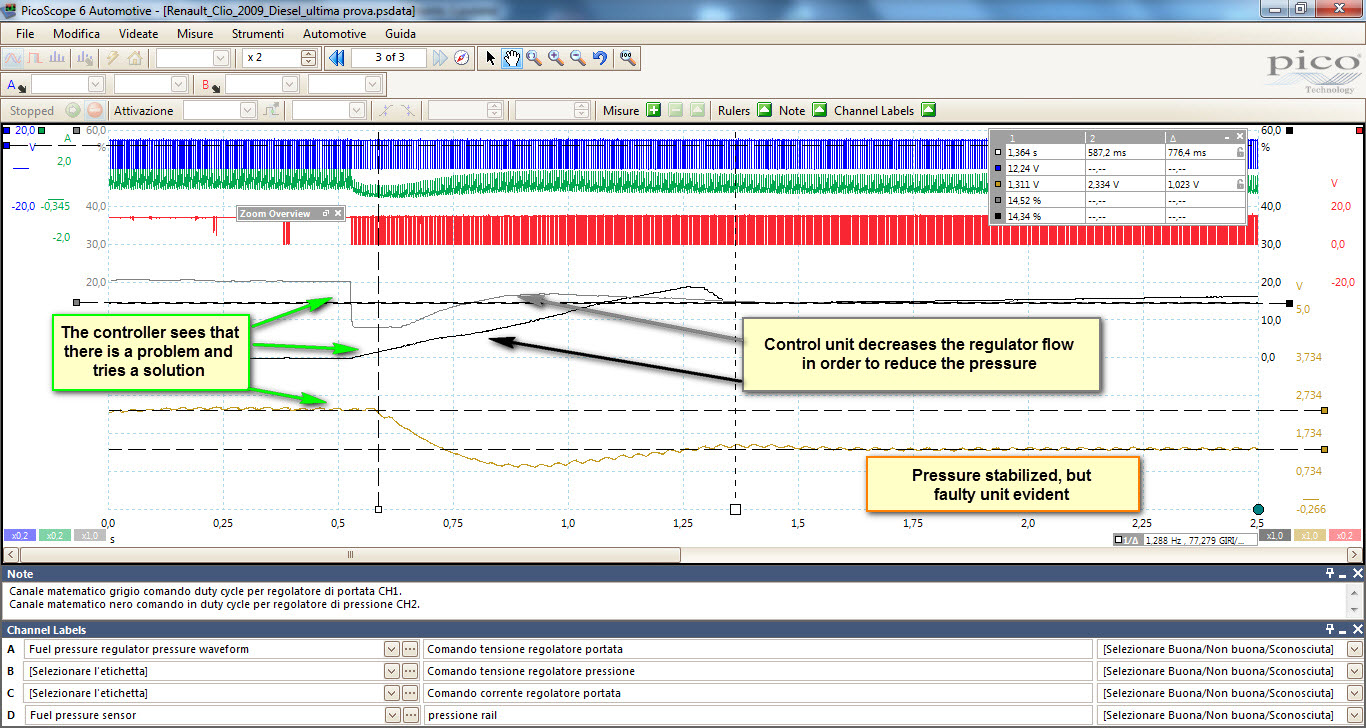

The first capture shows that just after engine start (we see the value of the PWM contro voltage), the rail pressure begins to rise to more than double what it should be. This explains the error codes and the classic knocking noise of a diesel engine.  What we immediately notice is that the pressure in the rail rises even if the signal from the pressure regulator is decreasing and even then the pressure does not drop to zero. This point should be 50 bar (just above 0.7 V) and this can be seen in the CHD waveform capture.

The control unit realizes that the pressure is too high and closes abruptly, driving the pressure down. This is known as the pressure response which is slow in the descent phase. Now after the period defined by the time rulers (see below capture), the pressure is stabilized but the engine MIL is switched on and the engine is in recovery mode.  My next move was to disconnect the pressure regulator and attempt an engine start. The engine should not start because the pressure in the rail should be only 50 bar. Instead the pressure stabilizes correctly, but the MIL remains on and the engine faulty.

As can be seen, the control unit through the flow regulator it is able to handle the pressure. Thus we can exclude the solenoid valve as the cause of the problem, as it does not regulate the pressure.

I decide to change the solenoid valve that I believe to be faulty. I believe it is not capable of opening to allow the output pressure from the pump to the rail. Running the test again I see the problem is still apparent with no noticeable improvement. I now believe the problem must be in the pump, particularly in the passageway that connects the pressure side with the pressure regulator, where there is a small filter. I removed the head of the pump, and with compressed air I tested the pressure regulator and confirmed with a degree of certainty there was no flow.  Unfortunately the filter is internal to the pump and I was unable to clean it. I decided to disassemble the pump and found the central shaft broken with clear signs of large internal bushing wear. With further investigation I also found a lot of filings in the diesel filter in the fuel tank, filings which blocked the flow to the inlet of the pump.

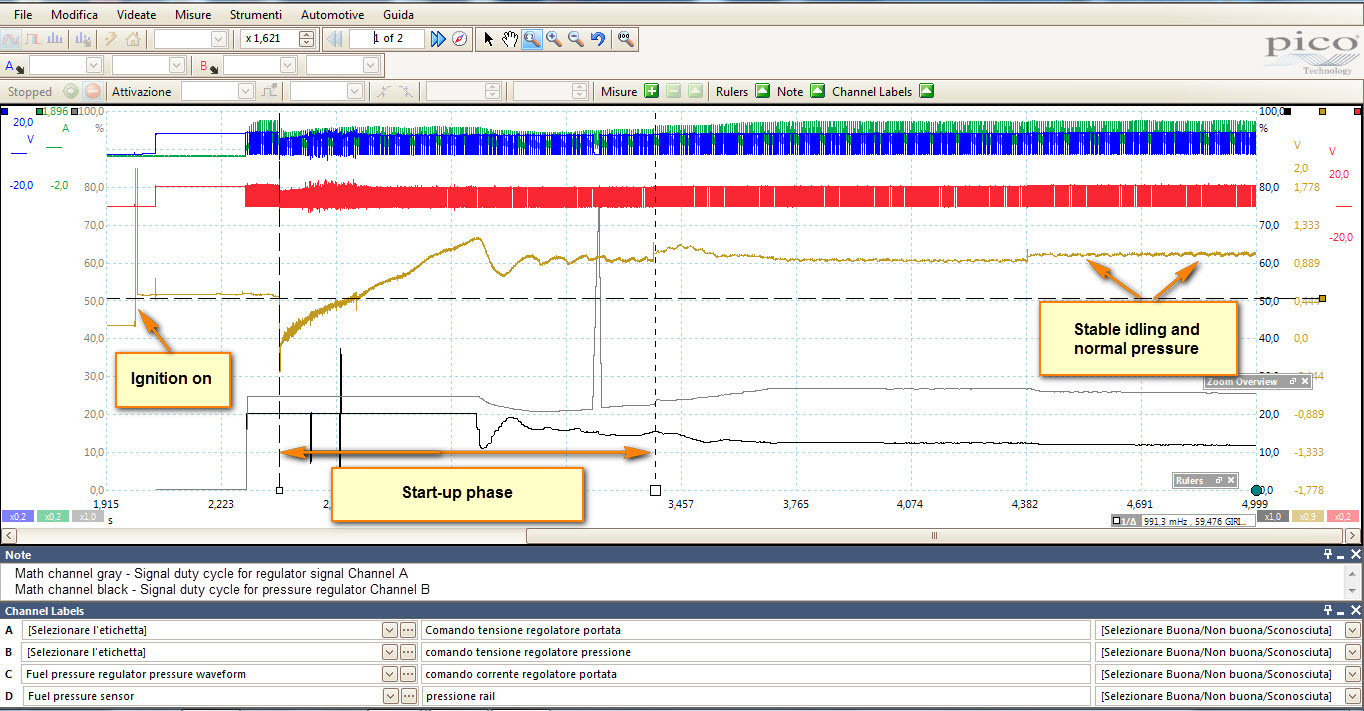

After major cleaning and the installation of a new pump the problem was resolved. The following capture was taken from the two solenoid valves and trend of the pressure in the rail.  |

|||||||||||||